New Workstations Improve Ergonomics, Efficiency

Credit: Valtronic Technologies

Manual assembly remains the most popular way to put together a product. Indeed, according to ASSEMBLY’s annual Capital Equipment Spending Survey, 87 percent of factories employ at least some manual operations to assemble their products. That figure has remained constant for the past 25 years, and it’s not all that surprising. After all, people are the most flexible assembly machines—just ask Tesla’s CEO Elon Musk!

Designing, equipping and managing a largely manual assembly process requires a different skillset than a highly automated one. The goal is to create workstations that minimize wasted motion or needless effort. Excessive twists or turns, uncomfortable reaches or pickups, and unnecessary walking all contribute to wasted motion. Tools, parts and other items needed to accomplish a task should be within easy reach. Work instructions and displays should be presented so technicians can easily see them. If your operation is mostly manual, the suppliers in this section can help you create a more efficient, flexible and ergonomic workplace.

If you’re looking to create a more ergonomic and efficient workplace, you’ll find what you need The ASSEMBLY Show South. Here’s a look at some of what you’ll see.

Click on the headings below for product information.

Engineered with a balance of durability and mobility, the WKB1000 workstation is suitable for workshops and assembly lines. The height-adjustable base creates flexibility for a wide range of employees, and various add-ons and work surfaces enable the workstation to be customized for any task. Each workstation is built from rigid, cold-rolled steel and equipped with an electric height-adjustment system that can lift up to 1,000 pounds. Casters and anti-vibration mounts provide toughness and mobility.

Add-ons for the upper frame include LED lighting, fan, pegboard, whiteboard, tool trolley, roll holder, flow rack shelf, tool bin bracket, shelves, paper tray, parts bins, PC hanger, monitor mount, and various ergo arms. Workstations come in more than 100 powder-coat colors, and a company logo can be laser-etched into the frame. Work surfaces include high-pressure laminate, butcher block, static-dissipative, aluminum, steel, stainless steel, plastic and vinyl. The workstation can be created to fit clean room environments.

BUILT Systems

www.builtsystems.net

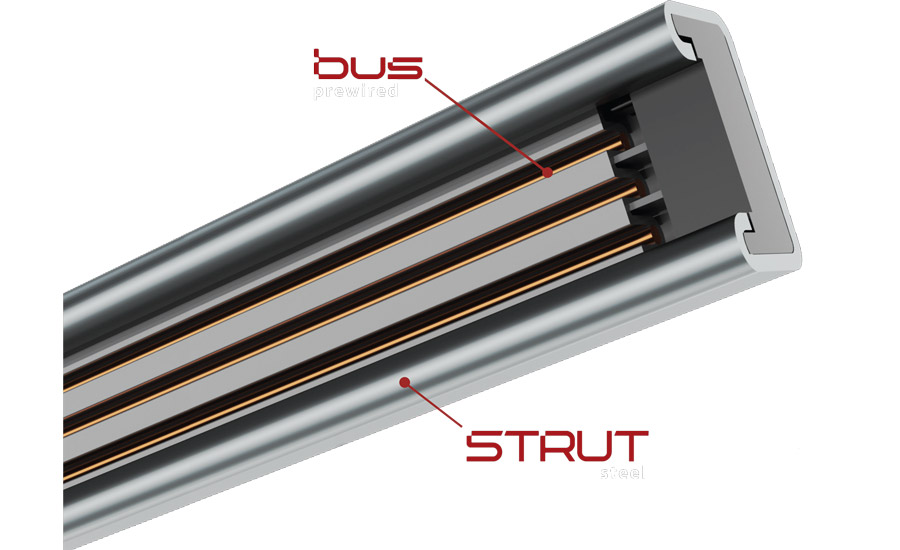

The busSTRUT system is a flexible, plug-in busway for distributing electrical power. Traditional plug-in style busways only allow tapping off power at specific intervals. In contrast, busSTRUT provides continuous open slot accessibility, which allows tapping into the system anywhere. Equipped with copper busbars, this low-voltage busway is listed for up to 600 volts. It meets UL and NRTL safety standards.

The systems consists of runs, crossovers, jumpers, feeds and attachments. Runs are the main component of the system, including pre-wired strut busways, hangers and joiners. These components are everything that is needed to create a suspended power distribution network. Crossovers are mechanical intersection components. Jumpers are electrical intersection components that energize an entire perpendicular row or column. Only one jumper is needed for an entire row or column. Feeds bring power to the system from the building’s back-panel electrical system. Attachments include lighting, power and data lines.

The slim, compact busway blends well with a building’s design, and is available in various finishes. Being a pre-engineered electrical distribution system, busways significantly cut down on labor and installation costs. They also make it easy to change factory layouts to meet future needs.

busSTRUT

https://busstrut.com

Creform has designed and built a stair-stepped mobile flow rack to be used line-side by an automotive parts supplier. The flow rack provides a seamless and organized flow of materials and helps reduce waste. The gravity flow rack assists in first-in, first-out inventory management. The compact design allows for line-side placement.

The unit is 63 inches tall, 66 inches deep and 66 inches wide, and it can hold up to 1,500 pounds. It is built from 28-millimeter pipe, which provides flexibility and reusability. (Higher capacity configurations are possible with 42-millimeter pipe.)

The flow rack features three supply levels and one return level in a stair-stepped setup. Each level has four lanes equipped with skate-wheel conveyors for shallow lane angles. The racks are suitable for both plastic returnable totes as well as cardboard boxes.

Lane dividers are located in the middle of each section of the rack and are used to organize the boxes to a specific lane. Each of the cart’s levels can be repositioned with simple tools. With the stair step design, each level can be raised or lowered without changing the length of the conveyor. This greatly simplifies adjustment.

The unit features six swivel-lock casters and three fixed in the center to allow for stability and ease of movement. Each caster can be locked in place.

The unit is built with blue pipes, but a variety of colors are available. Accessories include information sheet holders, label holders, tool storage, and hooks to hang tools and other supplies.

Creform Corp.

www.creform.com

Dalmec designed and built an ergonomic lift-assist system to enable a worker to pick up a refrigerator door from a roller conveyor, tilt it 90 degrees, and mount it to a metal cabinet. The device enables the operator to handle doors quickly, accurately and safely.

Lift-assist systems are designed and built in compliance with UNI EN standards EC Atex directives for safety. Manipulators are custom-built for each application.

Dalmec

www.dalmec.com

Industrial and alternating-tread crossover stairs are pre-engineered and can be designed to specific dimensions and applications. Systems are constructed in heavy-gauge, powder-coated and galvanized carbon steel, stainless steel, or aluminum, with a capacity of 1,000 pounds. All designs are built to precise dimensions and tolerances.

Crossovers with bolted access stairs are for applications without space restrictions. They have standard stairs that require more space to install, but they are also the most comfortable to use. For applications where space is limited, crossovers with alternating tread stairs are the best option. These stairs require the least amount of space, but the steeper angle is less comfortable.

Lapeyre Stair

www.lapeyrestair.com

Lift-assist devices are available 24-, 30- or 36-inch configurations and have a maximum capacity of 6,000 foot-pounds. They can be configured to travel on rails from most manufacturers, and they can be integrated with electric or pneumatic tractor drives. Optional features include infinitely adjustable hard stops with up to 300 degrees of rotation; rotation brakes; adjustable zone limit switches; festooning brackets, and cam latches for fixed rotational positions.

PowerBuilt

https://www.powerbuilt.net

FlowCell workstations are designed specifically for a facility’s unique operation. These durable and flexible flow racks support lean manufacturing principles by keeping inventory organized and maximizing pick efficiency. The cells can be designed for line-side storage, assembly cells, subassembly stations, material handling carts and supermarket areas. Racks can be configured with light, medium or heavy-duty SpanTrack rollers and wheel beds.

UNEX Manufacturing Inc.

www.unex.com